Click on images to enlarge

Sincropet is a specialist in manufacturing the best Elevator for any blowing machine

Sincropet is a manufacturer of blow molding machines for PET plastic bottles, offering solution in industrial plants ranging from 2,000 bottles / hour to 19,200 bottles / hour, with production for bottles from 150ml to 3.3 liters. In many projects, Sincropet assists the customer in the assembly of the factory, offering engineering advice for the complete packaging line, where the installation of "blower compressors" is necessary.

Sincropet has a dedicated professional department to purchase "blowing machine compressors", with the aim of reforming it to include in the sale for a new blow line.

In some cases, there is the possibility of reforming these "blowing machine compressors" by injecting technological up-grade into the reassembly, with devices that communicate with the blower more efficiently.

Sincropet is a company that is concerned with the human being and the preservation of the environment. That is why we are working on "compressor for blowing machine" reforms. It is a job that the company is proud to do when we recover end of life machines useful, we contribute to sustainability and reduce environmental waste.

Our department responsible for purchases of "compressors for blowing machine" rescues nature machines at all stages of use, to be reformed and recovered, as detailed in the three stages below:

- "Blower compressors" used in good condition - In this case, our engineers make an analysis of the equipment in operation, check if there has been a change from the original design, prepare a report to identify the necessary service and parts involved in the restoration, study possibilities in possible technological advances in this reform, aiming also resources that aim at the reduction of energy consumption, to then re-start it with higher technical level and sell it in the next line of blow.

- "Compressors for blowing machine" at end of life - are those compressors that are working in advanced stage of wear, in a precarious way, in this case, the company performs the same analysis above, with the visit of the engineers to also evaluate the vibration, resonance and noise of this equipment, evaluating the investment in disassembling and rebuilding this machine. After this study, the Purchasing department offers the proposal to buy, aiming to disassemble and reassemble this machine with new parts. This equipment would probably be spending an unnecessary amount of energy on production. After the refurbishment and rebuilding, Sincropet makes this machine available for sale and work efficiently and without wasting energy on the next wind line project.

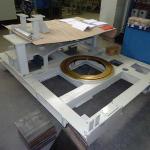

- "Blow and Compressed Blow Machine Compressors - These are those equipment that are plucked and disposed of in corporate yards. In this case, our purchasing department negotiates and purchases the equipment. After purchase, Sincropet will completely disassemble the compressor, recover parts in the structure, eliminate possible rust, apply the industrial painting process, reassembling this machine with improvements mentioned above to work more economically and be sold in the future.

- Sincropet develops advanced technology, providing the best cost-effectiveness against the quality and durability in sales of "blowing machine compressors".

To know more about blowing machine serviceCompressors for blowing machine

Call (11) 5851-6970 ou or click here and contact us by email.Gostou? compartilhe!